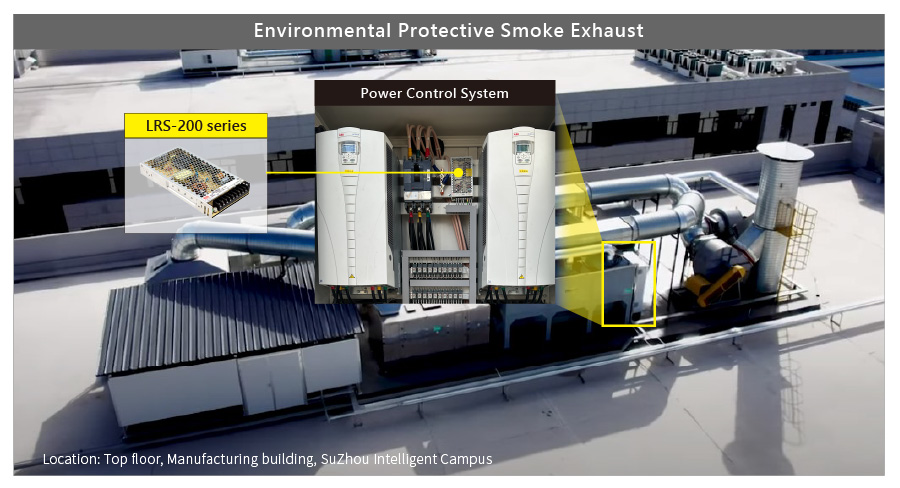

The exhaust gas generated during the production process may have a detrimental impact on the environment. MEAN WELL pays attention to environmental issues and plans to implement an advanced environmental protection smoke exhaust system (RCO) in the Suzhou New Park. The main functions are automatic switch control and remote monitoring of its normal operation. The impact of the exhaust gas on the environment is minimized.

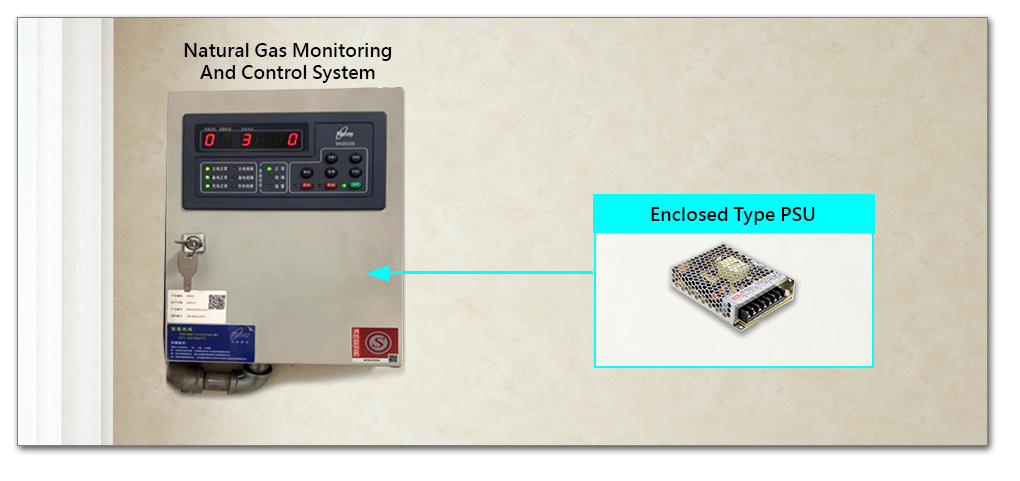

The natural gas monitoring and control system is important for safety in the kitchen and is one of the important measures for the kitchen to prevent major accidents such as natural gas leakage and ensure safe production. The detection system uses real-time detection of changes in the concentration of natural gas in the kitchen, and immediately warns if there is an abnormality, and informs relevant personnel to address the issue.

Application Example: Huadu MEAN WELL Application Example

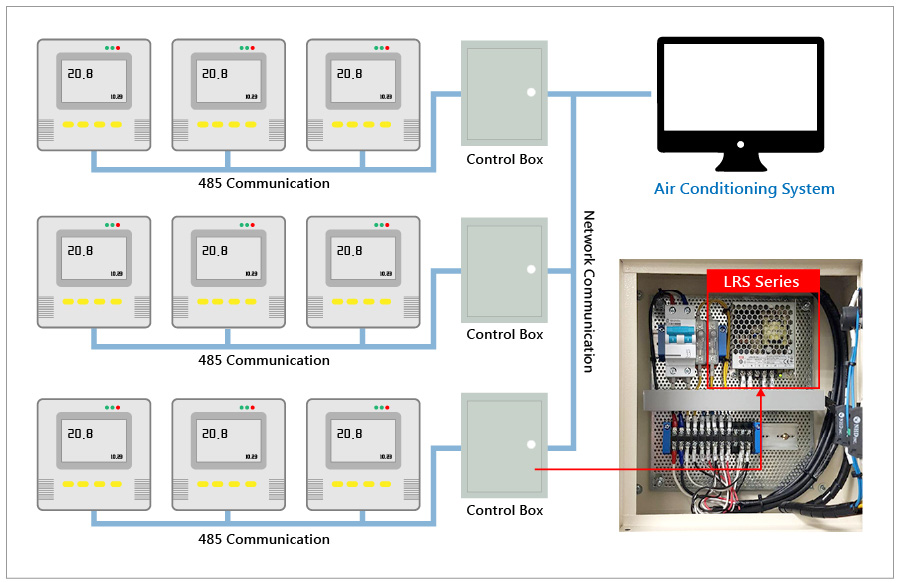

The temperature and humidity monitoring system not only provides a good office environment for employees but also ensure the quality of goods in storage. When the indoor temperature and humidity monitoring system detects an abnormality, the central air conditioning system can effectively adjust the temperature and humidity in the area in real time.

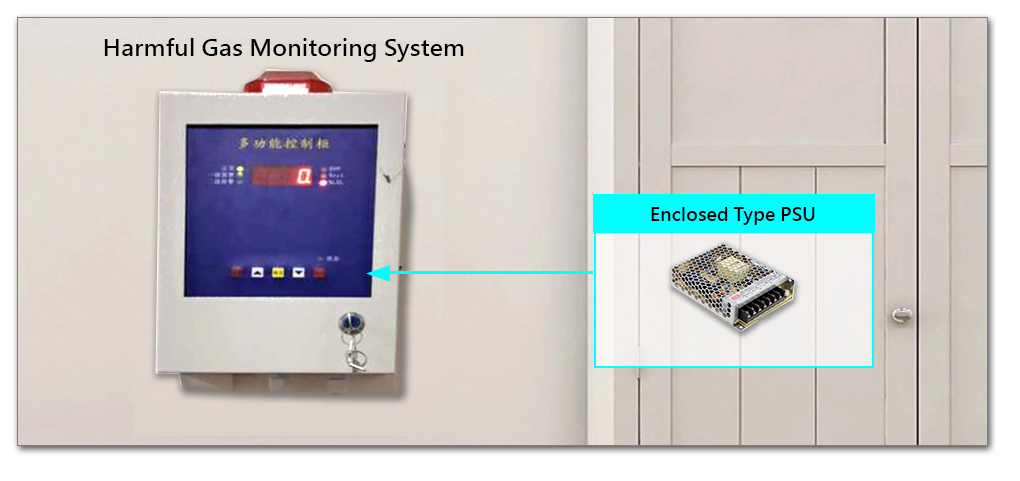

Implement air quality monitoring in office, production line, and pollution monitoring points to monitor the overall status and trend of air quality; regularly monitored substances in this campus are pollutants such as SO2, NOx, CO, benzene, and fluoride.

Application Example: GuangZhou MEAN WELL Application Example